September 2023 - Water

The month of August ended with a Yellow Jacket apocalypse but September began with hope. The vines were doing great and summer’s heat had waned. Was harvest on the horizon? Did the viticultural gods still have a few tricks to play? Answers to both were not far off.

As I continued to observe Yellow Jackets taking their toll on the Pinot Noir through the Labor Day weekend, testing for sugar was warranted. My immediate worry was not having Pinot to harvest. An early harvest would be better than none. Making a Rosé with a low Brix (sugar level) of 19 to 22 is an excellent option. Over 22, then red wine expand the possibilities. Mercy me a surprise, 25 it was. My first harvest was upon me.

Harvesting the following morning when cool was the desired approach. There was half a day to prep. I pulled out the crusher/destemmer from the shop and washed it down. I went into town and purchased half a dozen five-gallon food-grade buckets for holding the harvested grapes. I cleaned additional equipment and prepared a sanitizing solution. For the uninitiated, cleaning and sanitizing grape processing equipment is the overriding task winemakers are married to. Not unlike food preparation, bacteria can lead to spoilage. Keeping equipment clean and bacteria-free is the first step in good winemaking practices.

September 9, harvest began. I lifted the bird netting along the rows for easy fruit cluster access. Yellow Jacket damage resulted in a more time-consuming process. I had to carefully inspect each cluster removing dried berries and badly eaten sections. The cluster discard bucket filled almost as quickly as the acceptance bucket. Yellow Jackets loved the commotion. They were in swarming mode. I’m not sure how I accomplished it but the task was completed with no stings.

The tonnage haul you ask? 35 pounds. Yes, not exactly a great haul for my 50 or so third-year Pinot vines. Yellow Jackets had cut the harvest in half and the third year leans towards a small crop anyway. Next year I’ll have an additional 30 third-year vines, optimistically sans Yellow Jackets (topic for a future blog).

After crushing and destemming the grapes, into the fermentor, they went. I added a small portion of sulfite (to tame wild yeasts and bacteria) and stirred the must well, letting it rest for 24 hours. The next day, Red Star Premier Rouge yeast was added. The must fermented for 10 days.

As I was processing the Pinot, protective grape cluster bags were delivered. Each bag is nicely sized for completely covering a cluster, with a drawstring on top. Over two mornings, I individually wrapped 200 Riesling clusters. A bit tedious, but the prospective reward was motivating. Pinot harvested, Riesling protected. A euphoria ensued.

The previous four weeks had been manic, tinged with angst. At this comforting point, I could now relax, take on new tasks, and think more positive thoughts. This state of euphoria would not last long.

Two days later, I observed a lack of water coming into the cistern. The cistern provides all our domestic and landscaping irrigation, vineyard included. At first, I thought intermittent clouds might be the culprit. Depending on the level of cloudiness, the solar pump moving water 75′ uphill to the cistern may run at a slower rate or not run at all. As more sun made itself available during the day, it became clear one of my greatest fears for our property might come to fruition.

A pump or spring fail.

The first item to check was water availability. The spring is located 150 yards uphill from the pump house. Before trekking up there, I checked the pump house. Water associated with a second valve not connected to the pump had plenty of pressure. Good news, for the moment.

Next up, check the pump. A fuse associated with the power feed was intact. The wiring wasn’t disturbed. The float in the cistern connected to the pump, which shuts the pump down when full seemed to be working correctly. All looked well, but obviously it wasn’t. From my calculation, the pump had been operating for 12 to 13 years. The only conclusion was it had reached the end of its life cycle.

You can’t just go into town and purchase a solar pump. The Dankoff Solar SlowPump is a unique beast, and my solar array was built for it. I immediately ordered a new pump from the manufacturer in Oklahoma. On the plus side, the new pump would move water at 2.25 gallons per minute. Double the original pump. The upgraded dynamic would significantly ease water management issues during future summers, when vineyard needs clashed with domestic.

In the meantime, I had another pump. The High Lifter. The previous property owner had left it as a backup. As a piston pump, it uses the energy of water flowing downhill from the spring, to push a portion of it back uphill. No power is required. With the spring’s water pressure, the pump averaged half a gallon a minute. Although, unlike the solar pump, it operates 24/7. The downside, for every gallon the pump moves to the cistern, it discharges 4.5 gallons down the drainpipe. Usage translates to 5.5 gallons every two minutes.

In other words, a…lot…of…water.

Nevertheless, I installed the High Lifter.

Approximately 24 hours later, little water was coming into the cistern. The High Lifter was struggling. I closed the main valve and opened the second valve—barely a trickle. Had the spring been drained? To my knowledge, never in the life of the spring, had 3,960 gallons been withdrawn over 24 hours.

Gawd, I should have realized this could be a problem.

My first thought was to let the spring recharge. I waited 24 hours, then 48. Still a trickle. I trekked up the hill to check the spring. Peering down the top of the two breathing tubes at either end of the spring catchment area, revealed water. The ground between the two tubes was soggy, with water seepage along the lower side. Available water wasn’t an issue.

Could there be a blockage underground somewhere?

I reached out to a friend of mine, who recommended I have the North Fork Valley water commissioner Luke Reschke come out. He might have a few ideas. Luke was accessible and available. He thought there was a probable blockage underground at the spring head near where the perforated collection pipe meets the solid pipe bringing the water downhill. Or, in the pump house where there is a 2″ elbow, which narrows to 3/4 inch. Luke recommended a local Paonia contractor, Kendall Excavation. They apparently are experienced with springs.

Living in the valley you learn to cherish quality referral recommendations.

I wasted no time calling Kendall, undoubtedly with a bit of fear and anxiousness in my voice. They came out that same early evening to inspect the situation. A plan of action was soon forthcoming. First, they’d dig around the lower section of the spring to affirm water flow. If little flow, they’d correct the situation. Second, if water was leaving the spring unimpeded, they’d check the pump house where the 2″ pipe narrowed to 3/4″.

Kendall knew the lay of the land, I was comforted.

The next week, digging around the spring head they found a pipe two feet deep with a lid when opened, showed plenty of water. Back at the pump house, they cut the 2″ pipe below the elbow, and viola, an extended root ball was lodged where the pipe narrowed.

Problem found, and solved!

Paul Harvey, a well-known radio broadcaster from Tulsa, OK (my hometown) back in the day, had a well-known tagline for his program titled “The rest of the story”. Well, truth be told, this water tale took several additional turns and twists not revealed in my telling. I’m not going to tell the rest of the story, it’s a bit long and mind-numbing, i.e., doesn’t make good copy.

Suffice it to say, it took three weeks from the first discovery, till the new pump was installed on September 30. As the old saying goes, “All’s well that ends well”, and importantly, I certainly learned along the way.

After all that excitement, let’s turn to a more mundane topic—September’s weather.

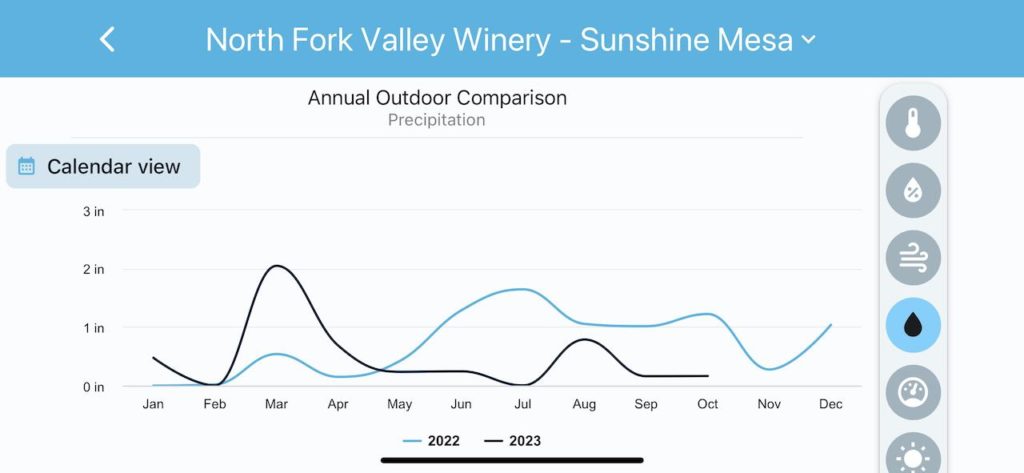

Big picture, mild and dry. Comparing this year to the last per the graph above, the trend of nominal precipitation since spring continued. Precipitation began strong early in the year but except for a small bump in August, it’s been dry. The graph illustrates the reverse for 2022. Per the U.S. drought monitor map released in late September, Delta County is now experiencing a moderate drought. A portion of the county a bit south and west of us is experiencing a severe drought.

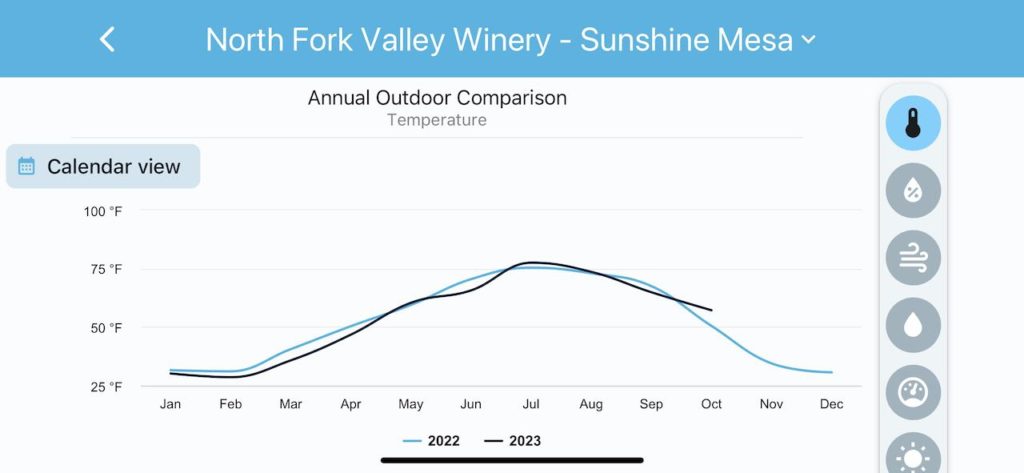

Per the graph below, temperatures between both years have mirrored one another.

For growers, mild and reasonably consistent weather patterns are our best friend. Though more often than not, you can always wish for more rain in western Colorado.

If anything this season, I’ve come to appreciate the essential role a third-year vineyard with its first harvest has in the life of the grower—acquiring experience and with it, knowledge.

A local grower mentor advised me earlier in the season about the importance of walking the vineyard rows daily. At times, you’re doing nothing more than stretching your legs and getting steps in. But more often than not, you’re observing ever-evolving dynamics whether driven by vine biology or forcing impacts of nature and activities not completely under your control.

You learn during this third year—what you nominally need to prepare for and the potential mitigating remedies. Thank goodness vine fruit production is light in the third year, a great opportunity to learn and grow with limited consequences.

See you next month in the vineyard!

The root ball is creepy looking, like an alien from out of space. Keep the puns coming!

Or something else as a dog owner you find in the yard, I won’d name it lol!